Following on from his seminar presentation at this year’s Fire Safety Event, held in April at Birmingham’s NEC, Dr. Karthick Govarthanam, General Manager for FIREFLY®, explores some of the issues surrounding fire risk in roof voids.

We have been assured in recent years by mainstream media that our firefighters’ main role nowadays is in educating the public as to the risks they face in their homes and installing smoke alarms. Yet the UK Fire and Rescue services were called out to 627,553 incidents out of which 67,014 of those involved primary fires in the year ending 2022. Between 2006 and 2008, at least 10,000 of these primary fires originated from the attic occurring in pubs, care homes and schools. Under fire conditions, smoke can travel at an alarming rate of 120 to 420 feet per minute. It’s no surprise then, that 57% of all fire-related fatalities occur outside the room where the fire started, according to insurance giant Aviva.

It is crucial then that Building Control Officers and others responsible for overseeing alterations in premises such as care homes and apartment buildings, turn their attention to roof hazards – with the most common being faulty electrical wiring, ceiling insulation, flammable roofing materials and leaky roofs. The latter could cause electrical wirings in the ceiling or attic to malfunction. Indeed, 41% of fire-related deaths in Great Britain were caused by the victim being overcome by gas, smoke or toxic fumes – and it can take as little as 2½ minutes for a home to be entirely engulfed in flames.

Dr. Karthick Govarthanam’s seminar at the Fire Safety Event in April.

A report published by BRE identified that the four mechanisms of fire spread in roof voids were combustible materials spanning beneath the non-combustible roof covering: absent or poor installation of cavity barriers/compartmentation, fire spread along the soffit, and heat transfer through penetrations. The document goes on to point out that ‘not many realise that the party wall (that’s the wall you share with your neighbour) should be completely intact with no gaps right up to the roof tiles.’

To mitigate against these lethal risks there are of course legislative requirements governed through the building regulations which includes Approved Document 7 for Materials and workmanship, Approved Document Part B – Volume 1 & 2 for Fire Safety and National House Building Council (NHBC) Standards. These documents explain how a large property can be compartmentalised and provides the guidance for minimum fire safety requirements. For example, minimum legal requirements for smoke and flame stipulate that a cavity barrier is required to prevent these products of combustion, i.e. smoke and flame, from penetrating and/or moving within a concealed space in a fire compartment for 30 minutes and are occasionally required to perform for longer periods of up to 120 minutes.

Legal requirements for insulation, meanwhile, state that a cavity barrier, when exposed on one side, should restrict the temperature rise of the unexposed face to be below 140˚C, over ambient temperatures, for 15 minutes – but are now usually fitted with a 30 minute - or greater barrier.

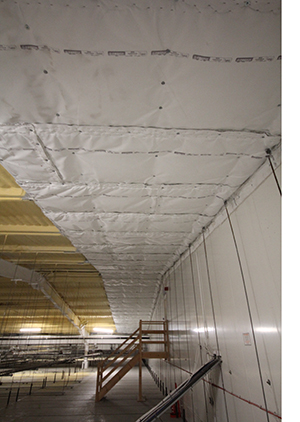

The technical support available to ensure compliant installation includes diagrams to illustrate the various types of cavity barriers, along with installed examples in roof voids, backed by high quality photography where appropriate as well as site supervision or inspections.

CRITICAL COMPARTMENTATION – Under Roof Tiles

CRITICAL COMPARTMENTATION – Under Roof Tiles

NHBC Standard’s Section 7.2.16, entitled ‘FIRE-STOPPING AND CAVITY BARRIERS,’ advises that compartment walls should stop approximately 25mm below the top of the adjacent roof framing and a soft fire-stopping material should be used, to allow for movement in ceiling or roof timbers. Whereas the ADB requires that gaps between compartments should be fire-stopped, using materials which achieve the same level of fire resistance as the compartment wall and that it should extend all the way to the underside of the roof covering. FIREFLY’s new Roof Cavity Closers have been designed to comply to both these contradicting requirements and still provide up to 60 minutes of fire protection.

In the wake of the Hackitt Report, construction professionals have been forced to take a more holistic approach to fire safety, both in design and execution of work, meaning we should not look at product solutions in isolation, which is why specifiers should carefully consider the ‘critical role of system components and compatible ancillaries’. Certified systems generally have a requirement for specified components to be used to maintain the integrity of the system. For example, with FIREFLY’s flexible barriers, joints would be formed using the stainless steel staples and high temperature adhesive and certain systems use stainless steel wire to stitch them together.

Finally, it is essential to acknowledge that service penetrations present an immediate and permanent threat to the integrity of any fire barrier of compartmentation strategy and that what is installed today could be compromised by new pipework of other installations at any time in the future, which is why FIREFLY® has developed and tested its system solutions to remain fully effective as long as service penetrations are correctly made and managed, using items like Collaroll which feature in many installations, wrapping pipes and isolated structural members, all helping keep occupants safe.

Left: FIREFLY® Zeus Horizontal and FIREFLY® Titan Lite in combination with FIREFLY® Collaroll and FIREFLY® Penowrap to offer continuous 60 minute and 90 minute protection.

Images © TBA FireFly

- Log in to post comments