An innovative anchoring solution from EJOT helps to optimise the aesthetics of externally insulated walls by preventing nuisance anchor marks forming on the rendered finish.

The ejotherm® STR U 2G is the latest generation of EJOT’s universal anchor washer, which was the first solution of its kind in Europe when it launched 20 years ago. It enables the countersunk installation of EWI (external wall insulation) systems or ETICS (external thermal insulation composite systems) covered with a cap.

Whilst ETICS has offered an efficient and durable way to optimise the energy performance of the building envelope for several decades, on the rendered walls of many buildings featuring an EWI system or ETICS façade ugly patterns of light and dark spots can often be seen. Known as ‘anchor marks’, these mean the locations of the anchors are clearly visible when they are supposed to be hidden, which is unattractive and disappointing for residents, but also a problem for contractors and specifiers.

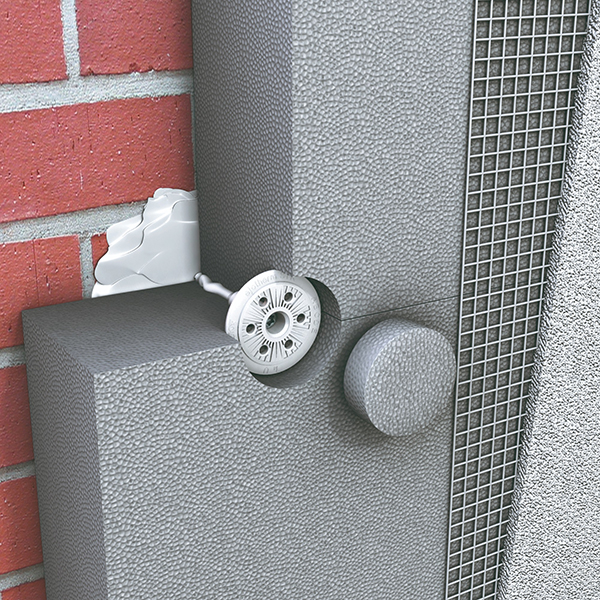

The EJOT STR U anchor in situ combined with a combi washer specially designed for mineral wool builds.

Anchor marks may be temporary or permanent spots on the rendered finish which become visible as darker or lighter spots above the anchor washer. This defect occurs regardless of the insulation material used and, whilst it does not impair the function of the system, the problem can grow over time to become more of a visual nuisance.

They are caused by a number of reasons and vary according to the location of the building, the orientation of the façade surface and the thermal bridge (Chi valve) of the anchor. Different heat storage capacities of the components used – such as insulation boards, anchors and render – and incorrect setting positions of the anchors can also lead to formation of the marks.

Where a dark spot develops in the area of the anchor washers, this usually stems from anchors being set too deeply, usually in an incorrect manner, which means they will have been filled or rendered after installation. The resulting thicker render layers over the anchors at these points means that the facade dries more slowly in these areas, which causes it to remain moist for longer. This allows for increased accumulation of dirt, algae and fungi, so at these points clearly visible dark discolorations form on the façade.

Anchor marks clearly visible on a façade which has been treated with an EWI system.

Lighter spots, on the other hand, are usually the result of different heat storage capacities or thermal conductivities of the components. The combination of anchor washer and render coating stores the heat longer than the undisturbed render surface, which means this area dries faster. The remaining surface of the facade stays moist longer and in turn collects dirt for a longer period – the area above the anchor washers stays bright. In the long term, the anchors become visible as light spots on the façade surface.

The EJOT ejotherm® STR U 2G prevents the formation of anchor marks because it allows for consistency in the layer of insulation. The combination of this special ETICS anchor design and matching insulating material caps means anchor marks can be avoided in the long term and unsightly spots can become a thing of the past.

EJOT ejotherm® STR U 2G is easy to use as it comes with a special installation tool. This allows the anchors to be installed in a recessed manner and sunk into the insulation material in a controlled way.

The EJOT STR solution in detail, showing the anchor and the insulating cap used to create a homogenous installation surface.

The installation tool cuts the area around the anchor washer and the insulation material is automatically compressed under the washer when the anchor is screwed in. An insulating cap can then be inserted flush into the recess between the anchor washer and the facade surface, allowing for a homogenous installation surface to be achieved.

The surface, which at this point is even once again, enables an even application of the render so that reworking in the anchor locations, as a result of them not being optimally placed, is no longer necessary. In addition, the temperature differences on the surface of the insulation board are minimised by the attached insulating material cap and the heat storage capacity is equalised over the entire surface. This way, an even and undisturbed exchange of moisture between render and insulating material can be permanently ensured.

Find out more about the EJOT STR solution for ETICS applications at www.ejot.co.uk/etics-expert-tips-one.

Image © EJOT

- Log in to post comments