By Andy Holland, Technical & Marketing Manager at Rapierstar.

Window and door technology has advanced significantly in recent years to the point where today’s profile systems, glazing and hardware enable housing specifiers to deliver ever safer, more secure and energy efficient homes. But for the benefits of these new generation products to be fully realised, it is crucial that the specification of window and door fasteners is not left to chance.

Selecting the appropriate fasteners is crucial for achieving desired performance outcomes, especially when constructing windows that meet the Secured by Design standards. The chosen screws must securely anchor hardware components, ensuring the structural integrity of the window and its resilience against forced entry. This consideration is but one facet of fastener selection.

Over thirty years, Rapierstar has advanced its portfolio of screws and fixings, enhancing the efficiency of fabricating and installing windows and doors. Our expertise has proven pivotal in developing hardware components, such as locks and hinges, for PVC-U and aluminium profiles. Today, Rapierstar is a leading innovator in construction technology, delivering quality and performance that surpasses the UK’s industry benchmarks and aids compliance with Building Regulations.

Fastener choices are critically important to deliver robust windows and doors, including the enhanced security Secured by Design standard.

Image © Shutterstock

Dual benefits – improved sustainability and safer manufacturing

In both new build housing and refurbishment projects, the durability and efficiency of window fixings are paramount. Hence why Rapierstar’s fixings are designed and tested to excel in these areas, providing a secure hold and reducing the likelihood of pull-out for long term performance.

This innovation, however, has also resulted in some important sustainability benefits through improved safety and efficiency during manufacture. For example, Rapierstar’s screws significantly decrease the amount of torque needed for driving them into place – in fact, up to 30% less. This reduces the amount of energy needed to power the tools used to assemble windows and doors and it helps to prolong cordless tools’ battery life.

But there are further benefits from a health and safety perspective. Operatives who assemble windows and doors using Rapierstar screws may be less fatigued and have less risk of repetitive strain injuries.

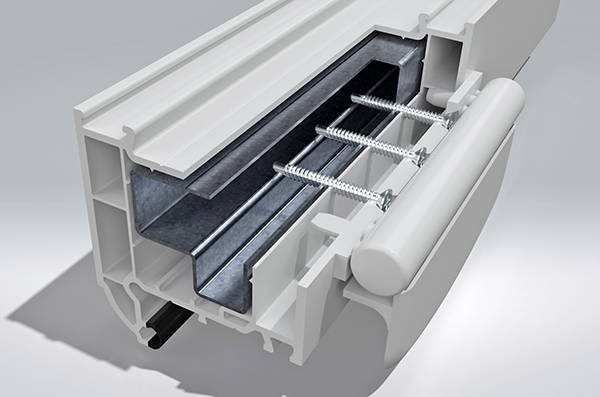

Rapierstar fasteners are purpose designed for the different materials used in window and door frames as this cross section shows.

Image © Rapierstar

Enabling a tailored specification and minimising local corrosion risks

In PVC-U window and door fabrication, Rapierstar presents the most comprehensive range of screws in the market, available in both carbon steel and stainless steel. This variety allows for fabricators to extend warranties, a crucial factor in social housing where long-term cost-effectiveness and maintenance reduction are vital.

Rapierstar’s carbon steel screws perform extremely well. They are designed for fast starting and exceptional grip, and undergo rigorous testing to replicate harsh conditions which ensures durability and reduced risk of corrosion. In coastal or polluted environments, however, Rapierstar’s stainless steel screws are ideally suited, offering exceptional corrosion resistance and suitability for extended warranty provisions.

The PVC-U window or door specification may also call for reinforcement to add strength and durability. Here, it is important to know your fasteners in terms of which screws work for unreinforced and reinforced PVC-U, and when they are reinforced, which should be used for steel versus composite materials such

as RCM.

Rapierstar’s commitment to specialised solutions here ensures that each product is optimally designed for its specific application, from easy installation to robust performance in demanding settings.

Rapierstar window and door screws are distinctively marked with a unique head stamp for easy identification of the metal type and brand.

Image © Rapierstar

Easier, more efficient installation

Where reliability and cost-efficiency on-site are critical, Rapierstar’s StarFix masonry screws offer a no-plug solution that simplifies installation while providing strong and durable fixings. The StarForm thread allows for easy, reliable, and repeatable installations in various substrates and it is ideal for multiple applications, from window and door frames to timber beams and facades.

Why choosing the Rapierstar brand makes a difference

Rapierstar’s screws and fixings provide a reliable, high-performance solution for social housing construction and maintenance. Their advanced design, compliance with standards, and suitability for various applications makes them an excellent choice for specifiers looking to ensure the durability, safety, and cost-effectiveness of their housing projects.

Find out more at www.rapierstar.com

- Log in to post comments