One of the most fundamental things any social landlord can provide is housing that is energy efficient. Not only will this help to futureproof their building stock, it also helps to tackle the rising issue of fuel poverty.

The introduction of Fabric Energy Efficiency standards (FEEs) in the last round of Building Regulation changes provided an assurance of minimum performance levels for new housing. However, as insulation levels have increased, the effects of thermal bridging have become more pronounced, and this can be a particular problem for the cavity wall constructions that are so popular throughout the UK. One of the simplest ways to treat heat losses from thermal bridges around openings, such as doors and windows, and at the same time help to comply with the Regulations, is with insulated cavity closers.

What is thermal bridging?

Linear thermal bridging describes the heat loss or gain that occurs at junctions between elements, and around openings in the building fabric, where there is an interruption in the insulation layer. This is taken into account when calculating the whole building fabric energy efficiency and carbon dioxide emissions, which determine whether or not the construction is compliant under the Building Regulations or Standards.

These bridges can be especially detrimental to the overall effectiveness of highly insulated constructions, as heat naturally flows through these paths of least resistance. They can also potentially lead to condensation problems, which may result in unsightly mould growth and eventual deterioration of plaster and paintwork.

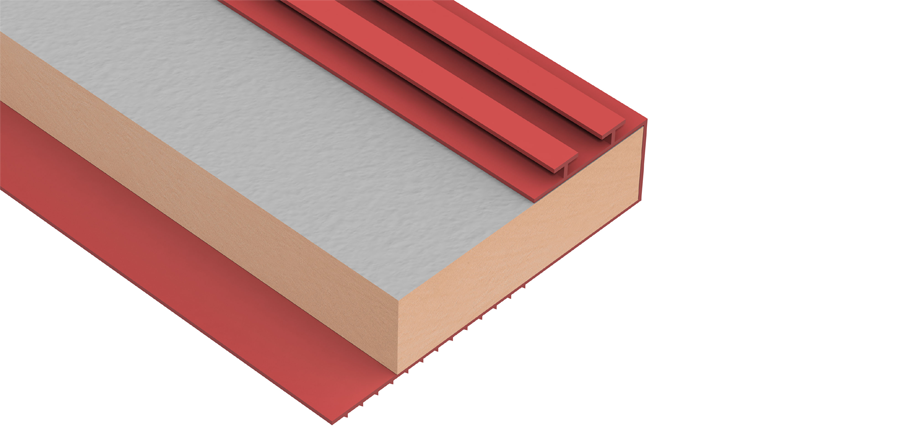

Insulated cavity closers can help to maintain a continuous insulated barrier around window and door openings and therefore minimise heat flow. They avoid the need for cut bricks, blocks or special reveal blocks, thereby simplifying and speeding up the construction process, saving both time and money, and importantly, making it easier to get the detailing right. Cavity closers can either be built in with frames or used to pre-form openings when frames are fitted later, helping to ensure the accuracy of opening sizes.

Cavity closers come with various types of insulation, but using a cavity closer with a premium performance insulant may not only improve the overall thermal efficiency of the building envelope, it can also include an integral damp proof barrier, effectively preventing the problems frequently associated with traditional methods of closing cavities and thermal bridging.

Can cavity closers help with compliance?

The Standard Assessment Procedure (SAP 2012) is used to calculate compliance with the Building Regulations and Standards for dwellings, and takes account of linear thermal bridges. The overall heat-loss associated with thermal bridging (or y-value) for a dwelling will vary, based on the lengths of junctions and their psi-values. Designers have three choices, they can either: use the default worst case y-value of 0.15W/m²K; use actual junction lengths and default psi-values for junctions built to the Approved / Accredited Construction Details (ACDs) which are published alongside the Regulations; or use actual junction lengths and actual associated psi-values for each junction.

The ACD’s offer a clear starting point on all projects; however, in order to both uplift the thermal performance and to increase the likelihood that it will match the design when built, it is worth looking beyond these basic requirements. The issue with doing this is the potentially bewildering array of calculations the designer is then presented with.

To make things simpler, Kingspan Insulation commissioned BRE Scotland to carry out thermal modelling of jamb and sill details using premium performance phenolic insulation cavity closers with thermal conductivities no greater than 0.022 W/m•K, in different commonly used wall constructions. The modelling drew on a number of key influencing factors to identify a worst case scenario, resulting in psi-values which are valid for a broad range of constructions.

By making use of premium performance cavity closers, it is possible to reduce thermal bridging without complicating the build, and to meet the requirements of both Regulations and tenants alike.

For further information and technical support please contact 01544 388601, email info@kingspaninsulation.co.uk or visit www.kingspaninsulation.co.uk.

- Log in to post comments