fire sprinkler boxing

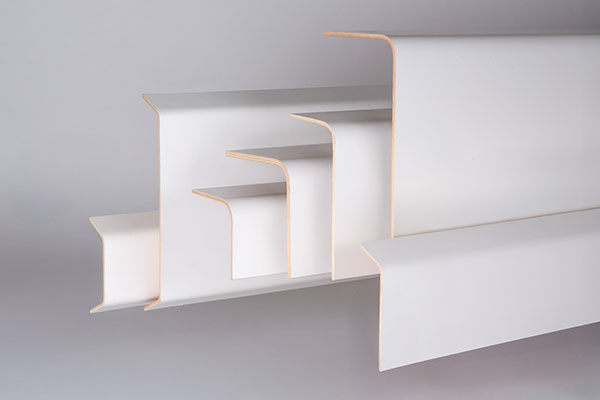

Vetta pipe boxing range - Encasement’s perfect finish

Wherever pipework needs to be concealed, the Vetta pipe boxing and casings range from Encasement can provide the perfect finish to a project, whether it’s a retrofit fire sprinkler, low carbon district heating upgrade or energy efficient heat pump installation.

Versa pre-formed pipe boxing is already installed in countless retrofit fire sprinkler projects to cover pipework in flats, lobbies and corridors, while for applications requiring a flame retardant solution, Versa FR pipe boxing provides an ideal solution.

Arma metal pipe boxing for energy efficient heating.

UK Boxings easily covers fire sprinkler pipework

When retro-fitting fire sprinkler systems, the UK Boxings range of pre-finished pipe and fire sprinkler boxing provides a consistent finish to installations by quickly and easily concealing pipework, which saves save time and money on site compared to site fabricated alternatives.

- Read more about UK Boxings easily covers fire sprinkler pipework

- Log in to post comments

Get in shape with Encasement pipe boxing

Whatever pipework you need to conceal, Encasement’s Vetta pipe boxing and casings range has a profile to match your requirements, while providing a perfect finish to the project, whether it’s a fire sprinkler retrofit, low carbon district heating scheme upgrade or heat pump installation.

- Read more about Get in shape with Encasement pipe boxing

- Log in to post comments

Simple, quick and practical pipe boxing from UK Boxings

Pipe boxing and decorative casings from UK Boxings have been used by housing associations and local authorities for well over 20 years to conceal, heating system, boiler, and fire sprinkler pipework to help improve a project’s finish, reduce time on site and save money.

Manufactured from 9mm thick, UKTR compliant and moisture resistant MDF, our pipe boxings and boiler casings are easy to fit and are used in ongoing RMI projects to interior heating system and retro-fitted fire sprinkler pipework, as well as boiler pipes and valves.

Pipe boxing for social housing – cover up with Encasement

Copyright © 2026. All rights reserved.

Designed By Euromedia Associates Ltd